Screw conveyor has the following characteristics

1) The structure is relatively simple the cost is low.

2) Reliable, easy to maintain manage.

3) Compact size, small cross section size small floor area. When loading unloading in the port, it is easy to get in out of the hatch car.

4) It can realize sealed transportation, which is conducive to the transportation of easily flying odorous materials, reduce environmental pollution improve the working conditions of port workers.

5) Easy to handle. The horizontal screw conveyor can be loaded unloaded at any position on its conveying line; compared with the screw reclaimer, the vertical screw conveyor has excellent recycling performance.

6) It can be transported in the opposite direction, the conveyor can also transport materials in two directions at the same time, that is, to away the center.

7) The unit energy consumption is large.

8) The material is easy to be crushed worn during transportation, the wear of spiral blade groove is more serious.

structural morphology

(1) There are three types of spiral blades of screw conveyor: solid spiral surface type, belt spiral surface type blade spiral surface type. The solid-state helical surface is called s-method, its helical pitch GX type is 0.8 times of blade diameter. Ls type screw conveyor is suitable for conveying powdery granular materials. The surface with helix is also called D method. Its spiral pitch is the same as the diameter of the spiral blade. Suitable for conveying powder small materials. Blade helical surface is rarely used, mainly used for conveying high viscosity compressibility materials. In the conveying process, the mixing mixing process are completed at the same time. The pitch of helix is about 1.2 times of the diameter of helix blade.

(2) The screw blades of screw conveyor have left-hand right-hand directions.

(3) Screw conveyor types include horizontal fixed screw conveyor vertical screw conveyor. Horizontal fixed screw conveyor is the most commonly used type. Vertical screw conveyor is used to lift materials in short distance. The conveying height is generally more than 8m. Helical blade is a solid surface type. It must have horizontal screw feed to ensure the necessary feed pressure.

(4) At the material outlet of LS, GX screw conveyor, 1 / 2 ~ 1 circle of reverse spiral sheet should be set to prevent powder blocking the end.

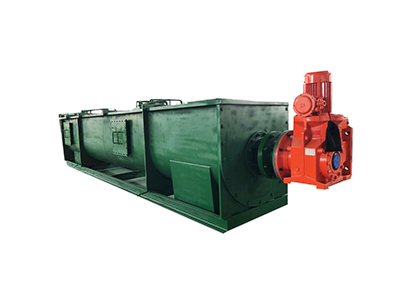

(5) The screw conveyor consists of three parts: the main body of the screw machine, the inlet outlet the driving device.

The main body of the screw machine is composed of head bearing, tail bearing, suspension bearing, screw, casing, cover plate base.

The driving device is composed of motor, reducer, coupling base.

application

Screw conveyor is widely used in various sectors of the national economy, such as food industry, building materials industry, chemical industry, machinery manufacturing transportation. Screw conveyor is mainly used for conveying various powder, granular small pieces of materials. Bulk materials transported include grains, beans, flour other foodstuffs, cement, clay, sand other building materials, salt alkali, fertilizers other chemicals, as well as bulk goods such as coal, coke ore. Screw conveyor is suitable for conveying materials that are easy to deteriorate, have high viscosity, are easy to agglomerate. In addition to conveying bulk materials, screw conveyor can also be used to transport a variety of goods. Screw conveyor the machine can complete mixing, mixing, cooling other operations while conveying materials. In port, screw conveyor is mainly used for horizontal vertical transportation of bulk materials in unloading trucks, unloading ships warehouses. The screw unloader, which uses the horizontal screw shaft to directly contact the material to unload the material layer by layer both sides of the vehicle, has many years of successful experience in domestic ports. The screw ship unloader, which is composed of horizontal screw conveyor, vertical screw conveyor related screw reclaimer, has become a more advanced type of continuous ship unloader, has been more more widely used in special cargo terminals at home abroad.